HCP Antibody Coverage in Biopharma Quality Control

When it comes to biopharmaceutical manufacturing, ensuring the highest level of quality control is non-negotiable. Host Cell Protein (HCP) contamination remains a major challenge in drug development, making HCP antibody coverage a crucial aspect of biopharma quality assurance. Without effective detection and quantification of residual HCPs, the safety, efficacy, and regulatory approval of biologics could be compromised. This article explores the significance of HCP antibody coverage, the challenges in achieving comprehensive detection, and best practices for optimizing biopharma quality control.

Why HCP Antibody Coverage Matters in Biopharma

During biopharmaceutical production, host cells, such as E.

coli, CHO cells, or yeast, are commonly used to express therapeutic proteins.

However, along with the target biologic, these host cells also produce

unintended proteins—HCPs—that can remain in the final drug product. Even at

trace levels, HCPs pose risks such as immunogenicity, reduced drug stability,

and diminished efficacy. Therefore, ensuring broad and robust HCP antibody

coverage is critical for detecting and eliminating these impurities.

Regulatory agencies like the FDA and EMA require extensive

HCP characterization to meet stringent quality control standards. Insufficient

HCP coverage can lead to regulatory delays, product recalls, or even market

rejection. To avoid these risks, biopharma companies must employ highly

sensitive and validated assays to detect HCPs effectively.

Challenges in Achieving Comprehensive HCP Antibody Coverage

Diversity of HCPs – HCPs consist of hundreds to

thousands of proteins with varying physicochemical properties, making it

difficult to detect all contaminants with a single antibody.

Limited Antibody Recognition – Polyclonal antibodies

are commonly used to detect HCPs, but their ability to recognize all possible

HCPs in a sample is limited. Poor coverage leads to undetected contaminants and

higher regulatory scrutiny.

Variability Between Cell Lines – Different cell lines

used in production can lead to varied HCP profiles, requiring customized

antibody development and validation for each process.

Insufficient Immunoassay Sensitivity – Enzyme-linked

immunosorbent assays (ELISA) are widely used for HCP detection, but their

sensitivity depends on the breadth of the antibody response. Inadequate

antibody coverage results in false negatives, potentially compromising product

safety.

Best Practices for Optimizing HCP Antibody Coverage

To overcome these challenges, biopharma companies must adopt

a strategic approach to HCP analysis and quality control. Here are some best

practices:

Develop High-Quality Polyclonal Antibodies

Polyclonal antibodies are critical for ELISA-based HCP

detection. To maximize coverage, antibodies should be generated against the

full spectrum of HCPs present in the production cell line. Immunizing animals

with a well-characterized HCP mixture ensures broader recognition and improved

assay performance.

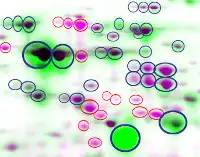

Validate Coverage with 2D Western Blot & Mass Spectrometry

While ELISA remains the gold standard, additional techniques

like 2D Western blot and mass spectrometry (MS) enhance HCP characterization.

These methods help confirm antibody coverage, detect low-abundance HCPs, and

assess batch-to-batch consistency.

Use Orthogonal Approaches for Higher Accuracy

A combination of ELISA, 2D gel electrophoresis, and LC-MS

provides a more comprehensive view of HCP profiles. Orthogonal methods ensure

that no major contaminants go undetected, strengthening regulatory submissions

and quality control processes.

Optimize Sample Preparation for Enhanced Sensitivity

HCP detection is only as good as the sample preparation

process. Using optimized extraction methods, high-resolution separation

techniques, and appropriate dilutions improves assay sensitivity, leading to

better identification of trace-level impurities.

Continuous Monitoring & Process Optimization

HCP profiles can shift throughout process development and

scale-up. Regular assessment of HCP coverage at different production stages

helps maintain process consistency and ensures that antibody-based assays

remain effective across different batches.

Regulatory Expectations for HCP Antibody Coverage

Regulators require comprehensive HCP characterization, and

failing to demonstrate robust antibody coverage can lead to costly delays. The

FDA and EMA emphasize:

·

Rigorous validation of ELISA kits with high

antibody coverage.

·

Use of orthogonal analytical methods to confirm

ELISA results.

·

Detailed documentation of HCP profiling

throughout the production cycle.

·

Justification of selected antibody reagents and

their effectiveness in detecting relevant contaminants.

To comply with these requirements, manufacturers must ensure

their HCP detection methods are scientifically sound, reproducible, and aligned

with regulatory guidelines.

Conclusion

HCP antibody coverage is a fundamental aspect of

biopharmaceutical quality control. With regulatory scrutiny increasing,

achieving broad and validated HCP detection is essential for ensuring drug

safety and efficacy. By leveraging advanced immunoassay techniques, orthogonal

approaches, and continuous process monitoring, biopharma companies can enhance

product quality while meeting global regulatory expectations.

For more in-depth insights on optimizing HCP detection

strategies, check over here

to access additional resources on best practices in biopharma quality control.

Comments

Post a Comment